New Semi

Basic Info.

| Model NO. | FG 020/040 |

| Usage | Inner Packing |

| Type | Packaging Sealing Machine |

| Packaging Material Mechanical Properties | Rigid Tray Sealing |

| Material Type | Bulk Solid |

| Speed | 2~4 Cycles Per Minute |

| Dimensions | 804mm*1380mm*1844mm |

| Delivery | 65 Days From Receipt of Deposit |

| Material | 304 SUS |

| Transport Package | Plywood Case with Steel Foundation |

| Specification | CE |

| Trademark | Utien |

| Origin | China |

| HS Code | 84224000 |

Product Description

New Semi-automaic Tray Sealer for Food/Ready Meals/Meat with Modified Atmosphere Packaging

Product Description

Semi-auto tray sealer:Utien Tray sealers are perfect for preformed trays of almost any size or shape. With various packing options and high capacity, we produce attractive, leak-proof,tamper-evident packages with greater seal integrity and extended shelf life.Our tray sealers have been widely applied in many industries, such as medical, food, and hardware. We pack all types of sausage, meat, poultry, seafood, prepared food, and cheese to their best presentation.

Detailed Photos

More application

Our Advantages

1) Customizing capacity-- 200~2,000 trays per hour.

2) Multifunction---vacuum gas flush, vacuum skin packing, or both combined.

3) Easy operation---by finger touch on PLC screen.

4) Reliable quality---spare parts of international top brands.

5) Flexible design--- Various package shapes, volume, and output.

Product Parameters

Machine details:

TOP SAFETY

Safety is our top concern in machine design. To ensure the security of workers and the machine, many safety sensors are installed and special designs are made for max safety.High hygiene:Most of the machine material is food-grade stainless steel. And we ensure every tray is packed under circumstances of high hygiene.Flexible packing options:Here are MAP, skin pack, or both combined for different productsTechnical Data

| Working Parameters | |

| Package Type | Sealing/MAP/VSP |

| Speed | 2-3cycles/min |

| Tray Quantity/mold | 2/3/4 |

| Tray Shape | Circular,Oval or Rectangle |

| Top Film | |

| Material | Sealable PE\PA Multi-layer Co-extruded Plastic Film |

| Pre-printed Top Film or Transparent Top Film | |

| Roll Diameter | 250mm at most |

| Thickness | ≤200um |

| Components | |

| Vacuum Pump | BUSCH |

| Electrical Components | Scheneider |

| Pneumatic Components | SMC |

| PLC Touch Screen & Servo Motor | DELTA |

| Machine Parameters | |

| Dimensions | 804mm×1380mm×1844mm |

| Weight | 500kg |

The parameter in this sheet is for reference only, some of the data may be different with different cases.

New Semi-automaic Tray Sealer for Food/Ready Meals/Meat with Modified Atmosphere Packaging

After Sales Service

1. WARRANTY1) The whole machine has 12 months warranty exclude wearable parts such as silicone plate, film, heating elements, and so on.2) Special oversea engineering service is not included in the warranty.3) Other items or services require can be negotiated.2. Information1) We offer information about packages and machinery before making a special offer.2) We have multiple after-sale services include online guiding, engineering service, installation & tuning service, and so on.3. Design1) We can provide package design service at the request of the customer.2) We can customize machine function, appearance, and special requests within a reasonable range.3) We can make a certain design of the package under request.

FAQ

Q1:How long does it take to deliver the machine after the order & deposit?

A1:Usually it will take 60 working days to manufacture the machine and make it ready to deliver. At first 30 days, the technical drawing will be made. The second 30 days start manufacturing the parts and ready to deliver.

Q2:What do you need to make a specific offer for my product?

A2:To make a special offer we will need the dimension(s) of the package(s) you want to use on this machine. We also need the approximate production volume you need per day. If with other special request please also inform us before we make the project.

Q3:Can you offer overseas service?

A3:Yes, if request. But we suggest online problem solving at first. If the problem still shows we can arrange engineer to go to your factory personally to solve the issue.

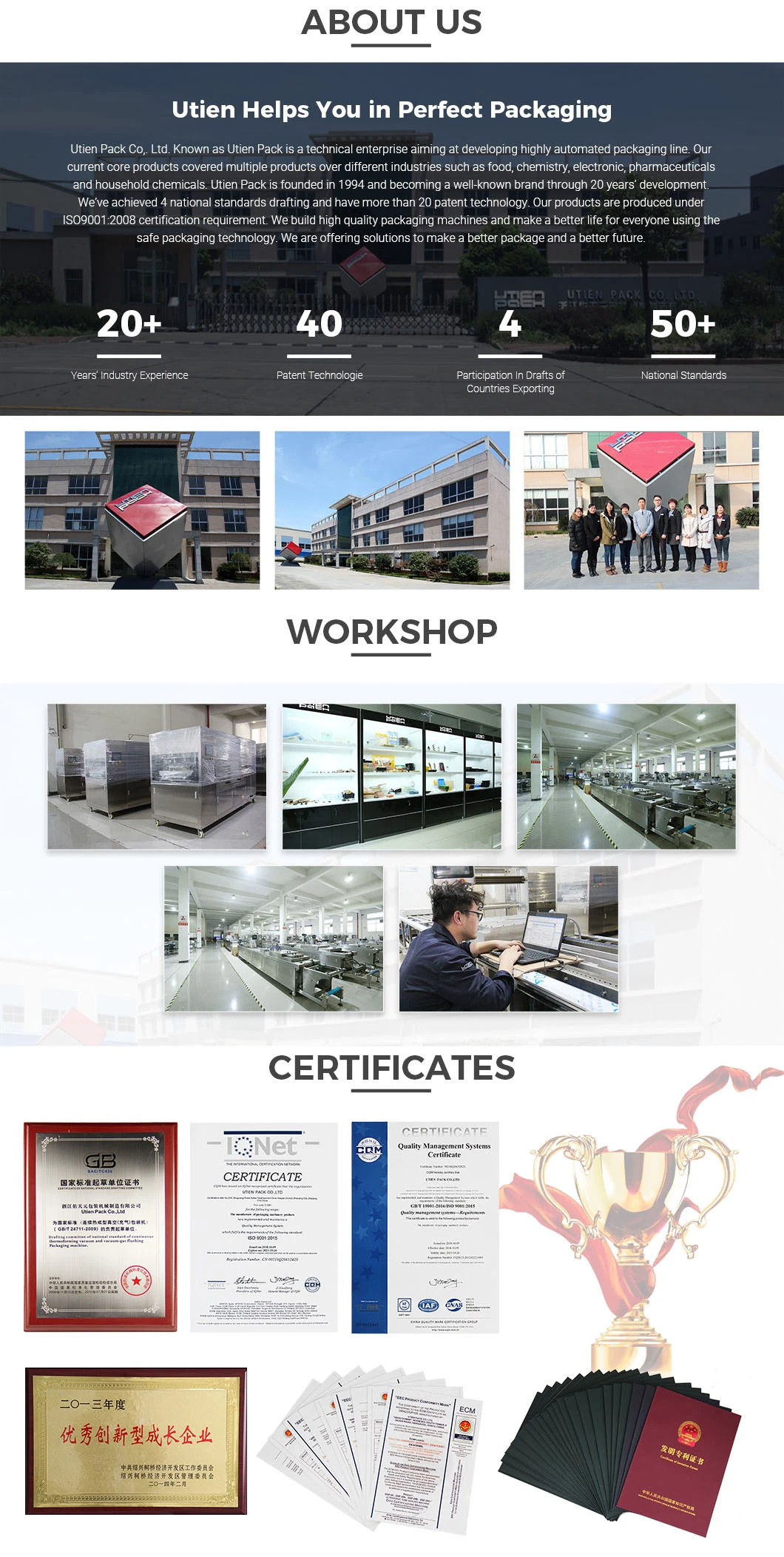

Company Profile